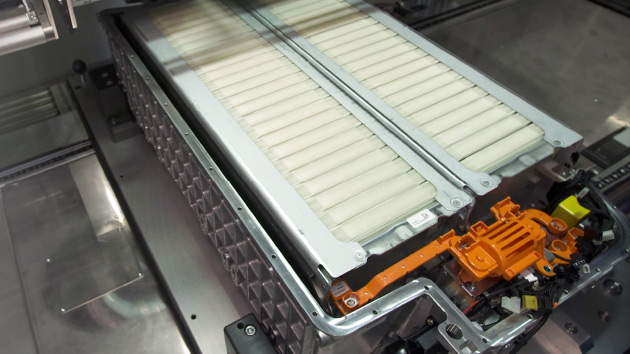

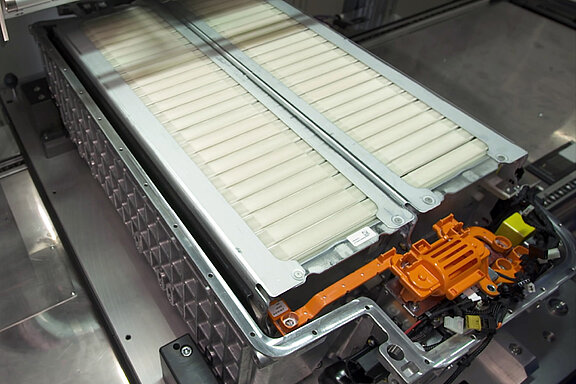

SIVONIC's Multi-channel EIS meter is a sophisticated and versatile device that plays a central role in the battery industry. Thanks to its ability to precisely analyze crucial parameters such as the state of charge (SoC) and state of health (SoH) of battery cells within a battery module, the EIS meter has established itself as an indispensable tool for quality and performance assessment.

Basics of the EIS meter from SIVONIC

The EIS meter is based on the analysis of the impedance spectrum over a wide frequency range. This provides in-depth insights into the electrochemical and mechanical properties of batteries. This detailed analysis allows manufacturing errors, structural deviations and other anomalies such as material defects or mechanical faults to be detected at an early stage. Such anomalies can result from production errors, faults in manufacturing processes or insufficient material quality.

Applications of the Multi-channel EIS meter in quality control

The Multi-channel EIS meter from SIVONIC has a wide range of applications in the quality control of battery modules including the individual battery cells. In addition to fault detection, it is used to evaluate the long-term performance of batteries. Ageing processes, changes in internal resistance and electrochemical degradation processes can be precisely identified and quantified.

A particular advantage of the Multi-channel EIS meter is its non-invasive nature. The technology enables battery parameters to be monitored without the need for physical intervention. This improves both operational safety and the efficiency of production processes. The EIS meter plays a crucial role in end-of-line (EoL) and beginning-of-line (BoL) testing in particular. It ensures that only qualitatively flawless modules pass through production or the delivery process.

Integration of the EIS meter in automated production processes

The integration of SIVONIC's EIS meter into automated production lines is revolutionizing battery production. Modern test systems combine the functionality of the EIS meter with advanced algorithms such as machine learning to efficiently analyze large amounts of data. This increases the precision of fault detection and further improves the prediction of battery performance.

SIVONIC's EIS meter is characterized by high robustness, outstanding measurement accuracy and reliability even under demanding production conditions. Its seamless interfaces enable real-time synchronization with existing process control systems. This reduces delays, increases production speed and minimizes potential production downtime.

Advantages of real-time analysis with the EIS meter

Real-time processing of the data obtained by the EIS meter brings considerable advantages for production control. It enables immediate detection of deviations and proactive countermeasures, which sustainably improves production quality. At the same time, automated systems help to reduce costs by minimizing manual intervention and lowering the error rate.

Future prospects

With the growing demand for high-performance and long-lasting batteries, especially in electromobility and stationary energy storage, the importance of SIVONIC's EIS meter will continue to increase. Advances in sensor technology, data processing and integration in Industry 4.0 environments will further increase the range of applications and efficiency of this method.

Conclusion

SIVONIC's EIS meter is a key tool in the quality control and performance evaluation of battery modules. Its versatility, precise analysis options and seamless integration into modern manufacturing processes set new standards in battery production. With the innovative technology of the EIS meter, the benefits of electrochemical impedance spectroscopy can be maximized. This not only supports the optimization of production processes, but also the development of high-quality and reliable battery modules for the future.

![Fuel Cell [Translate to Englisch:]](/fileadmin/_processed_/e/2/csm_img_Vorschau_Applikationen_Brennstoffzellen_5c9d48bd57.jpg)

![Electrolysis [Translate to Englisch:]](/fileadmin/_processed_/c/5/csm_img_Vorschau_Applikationen_Elektrolyse_010bb10ebc.jpg)

![Corrosion [Translate to Englisch:]](/fileadmin/_processed_/b/0/csm_img_Vorschau_Applikationen_Korrosion_1a39355e33.jpg)